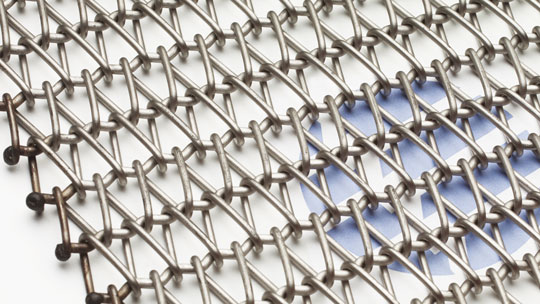

Any industrial setting requires the selection of a conveyor belt that is appropriate for optimizing performance and efficiency. A woven mesh conveyor belt is highly regarded for its versatility and functionality among the various types of conveyor belts. In addition to durability, hygiene, and adaptability, wirebelt systems use woven mesh belts. In order to select the most appropriate woven mesh conveyor belt for your application, you must consider several factors. This article explains the key considerations you must make.

1. Determine the requirements for your application

It is crucial to identify the application requirements when choosing woven mesh conveyor belts. Different applications have different requirements for load capacity, temperature resistance, and material handling.

- Load Capacity: Your conveyor belt’s load capacity depends on the weight and size of the materials it will handle. You should ensure that the belt you choose can handle the maximum load without stretching or deforming. Woven mesh conveyor belts come in different wire gauges and mesh sizes, which affect their load-bearing capacity.

- Temperature Range: You should consider the temperature range the belt will be exposed to when choosing a conveyor belt. It is possible to design woven mesh conveyor belts to withstand high temperatures, making them ideal for baking, metal processing, and glass manufacturing. Ensure the belt material is compatible with your operation’s temperature range.

- Material Handling: It is important to identify the materials that will be conveyed. Woven mesh belts are ideal for applications requiring high airflow, drainage, or easy cleaning. Food processing is one example where woven mesh belts are often used due to their hygiene.

2. Make sure you choose the right wire material

A woven mesh conveyor belt’s wire material plays an essential role in its performance and longevity. It is generally made from stainless steel, carbon steel, and a variety of alloys.

- Stainless Steel: In applications involving moisture, chemicals, or high temperatures, stainless steel is a popular choice due to its corrosion resistance and durability. Food processing, pharmaceuticals, and other industries that prioritize hygiene use it frequently.

- Carbon Steel: There are several types of carbon steel, all of which are more economical than stainless steel. Carbon steel is less corrosion-resistant than stainless steel and should not be used in environments with high moisture or corrosive substances.

- Alloyed Materials: Materials with alloys may be required for specialized applications, such as those involving high temperatures or chemicals. Consult with manufacturers to determine what alloy best suits your requirements.

3. Make sure the mesh is the right size and configured correctly

Conveyor belt mesh sizes and configurations affect their performance in various applications. Mesh size determines how well the belt supports and transports materials while allowing drainage and airflow.

- Mesh Size: Choosing the right mesh size for your material handling needs is crucial. Smaller mesh sizes are ideal for conveying small or delicate items, while larger mesh sizes are ideal for conveying larger items and applications requiring more drainage.

- Configuration: In addition to plain weaves, twill weaves, and Dutch weaves, woven mesh belts come in different configurations. You should select a configuration that meets your application’s mechanical and operational requirements. The weave pattern determines the belt’s strength, flexibility, and open area.

4. Determine whether the product needs to be maintained and repaired

In order to reduce maintenance costs and guarantee long-term performance, woven mesh conveyor belts should be durable. Although woven mesh belts are typically known for their robustness, factors such as wire thickness, weave pattern, and material choice play a role in how durable they are.

- Wire Thickness: thicker wire will offer greater strength and durability, allowing it to be used in heavy-duty applications. However, it is less flexible and may cost more in the long run.

- Weave Pattern: The weave pattern influences the belt’s flexibility and resistance to wear and tear. For instance, a twill weave provides increased flexibility and strength, while a plain weave offers simplicity and cost-effectiveness.

- Maintenance: Keeping your woven mesh conveyor belt maintained is critical to extending its lifespan. Consider the ease of cleaning and inspection when choosing a belt. Woven mesh belts are usually easier to clean and maintain than other types.

5. Get expert advice

A woven mesh conveyor belt manufacturer or expert can offer valuable insights and recommendations when in doubt. In addition to assessing your application’s requirements, they can recommend suitable belt options, and help you customize and install them.

- Manufacturer Support: You can contact manufacturers such as Wirebelt that offer woven mesh conveyor belts. They can provide detailed product information, and customization options, and help you choose the right belt for your needs.

- Technical Advice: Advice on Application: Consult with a belt specialist to ensure that your chosen belt meets all operational and regulatory requirements. This will help to prevent compliance, safety, and performance issues.

Conclusion

Choosing the right woven mesh conveyor belt for your application requires a thorough understanding of your operational needs and careful consideration of various factors, including load capacity, temperature resistance, wire material, mesh size, and durability. In addition to providing robust and versatile solutions for various industrial applications, wirebelt systems offer a range of options that can be tailored to meet specific requirements.

Using woven mesh conveyor belts, you can ensure performance and longevity by defining your application requirements, choosing the right wire material, and consulting with experts. Your conveyor system operations will be more efficient, reliable, and safe if you implement these considerations.